Optimal welding solutions for

the fabrication and processing of coil joints

Coil joining

The requirements on coil joints are constantly increasing.

For this reason, we rely on the benefits of laser welding technology – high welding speeds and excellent welding quality.

IDEAL arc welding machines cut and weld coil of various qualities and material combinations using a laser beam in a clamping device.

We offer flash butt welding and arc welding machines in semiautomatic or fully automatic versions with integrated coil end shears for smaller coil dimensions. Reliable MIG/MAG, TIG or plasma welds are produced, which serve the continuous coil replacement without interruption.

IDEAL coil joining machines are utilised in:

- Etching lines

- Coating lines

- Continuous annealing lines

- Inspection lines

- Press and punch lines

- Profiling lines

- Pipe fabrication lines

- Galvanising lines

- Pitch lines.

On all machine types, the compact and robust machine design with intuitive operator guidance is oriented towards industrial usage in production.

During the designing of the LBS and LAS machine types, the operator was the main focus. For this reason, particular emphasis was placed on the simple and ergonomic operation.

Used around the world, IDEAL coil welding machines have been proving their quality and reliability on a day-to-day basis and have been doing so for decades.

Application Examples

Coils of various qualities and coil dimensions can be processed on the coil joining machines.

Get to know our solutions

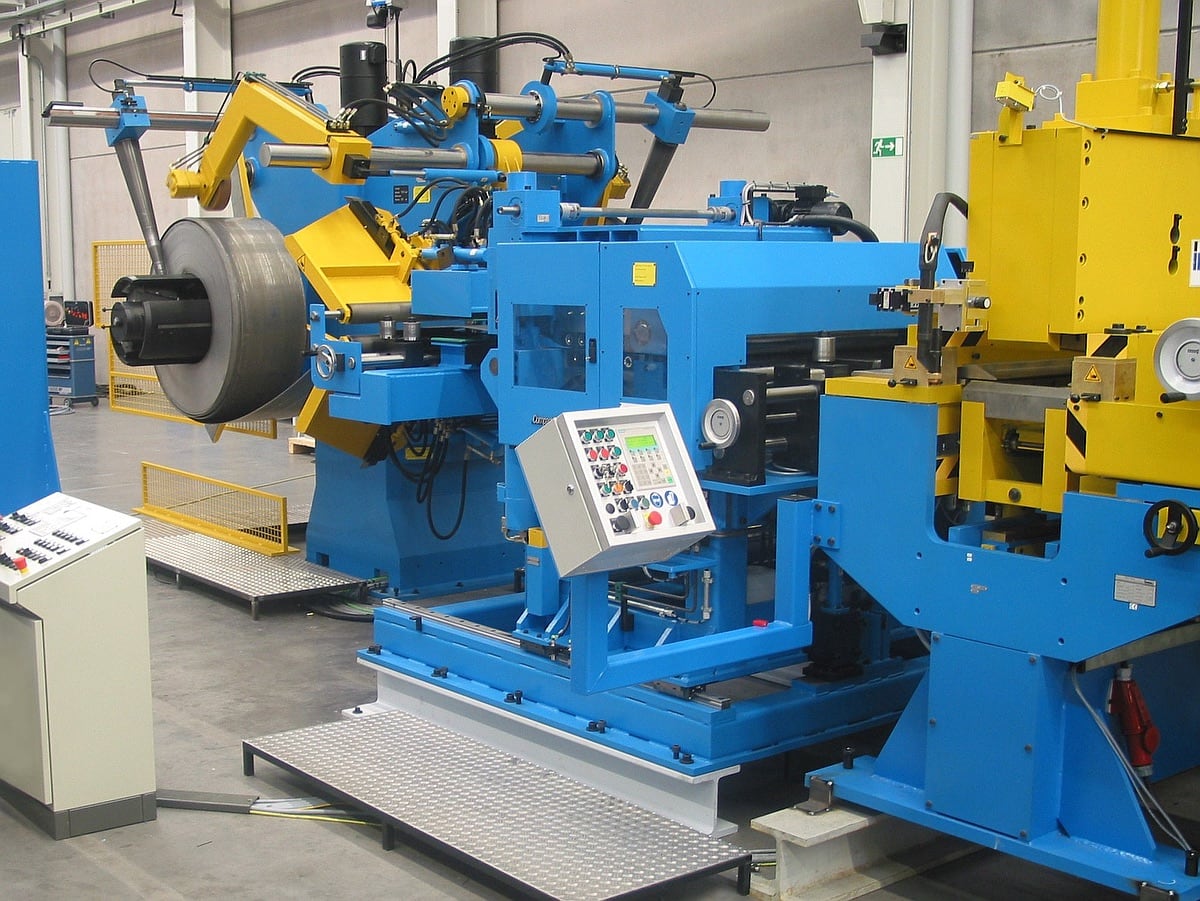

Type LBS coil joining machines

Type LBS coil joining machines are the affordable variants for the welding of coils.

The LBS machine line offers a varying degree of automation in regard to the handling of the coil ends. Everything is possible from manual to fully automatic handling.

Due to the utilised welding process, the coils are joined in a very rational and cost-efficient manner.

Optionally, the machines can be equipped with various accessories.