Laser precision seams– Type LAS coil welding machines

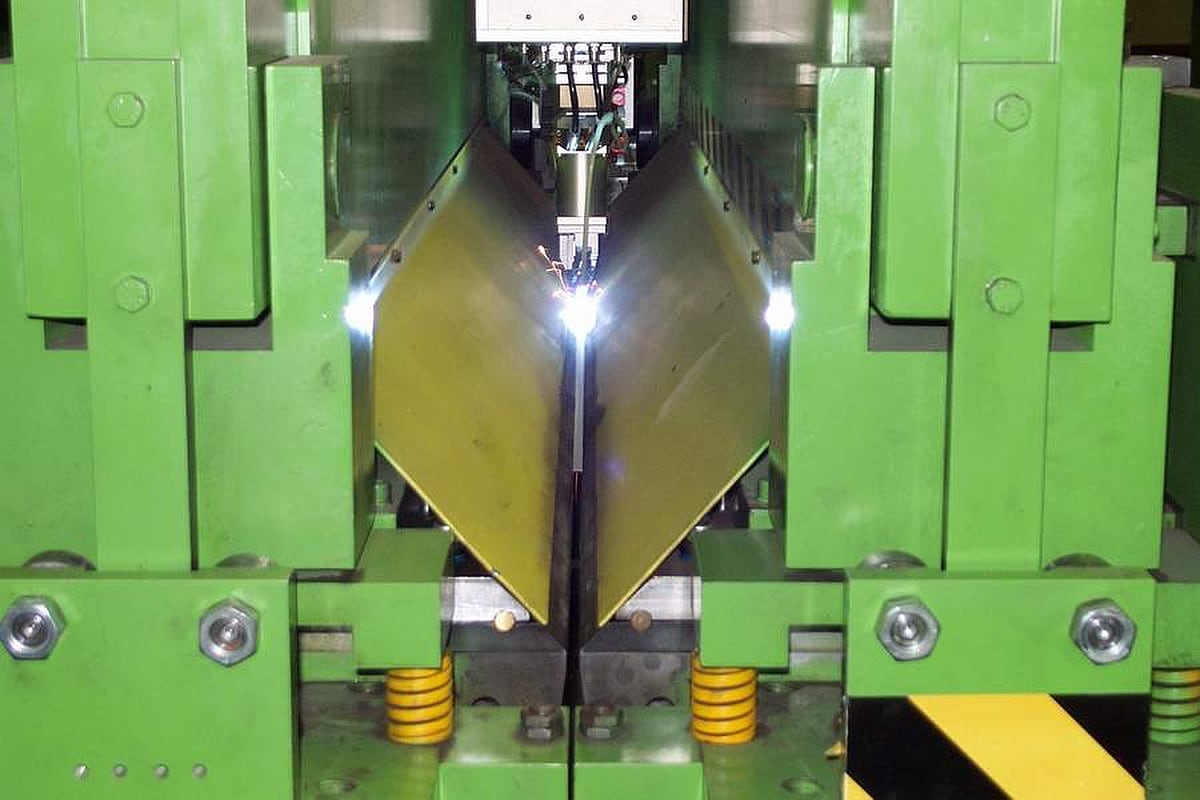

The precise laser transverse seam coil joining machines for flat, high-grade weld seams with coil to coil joints in various material combinations and with different coil dimensions

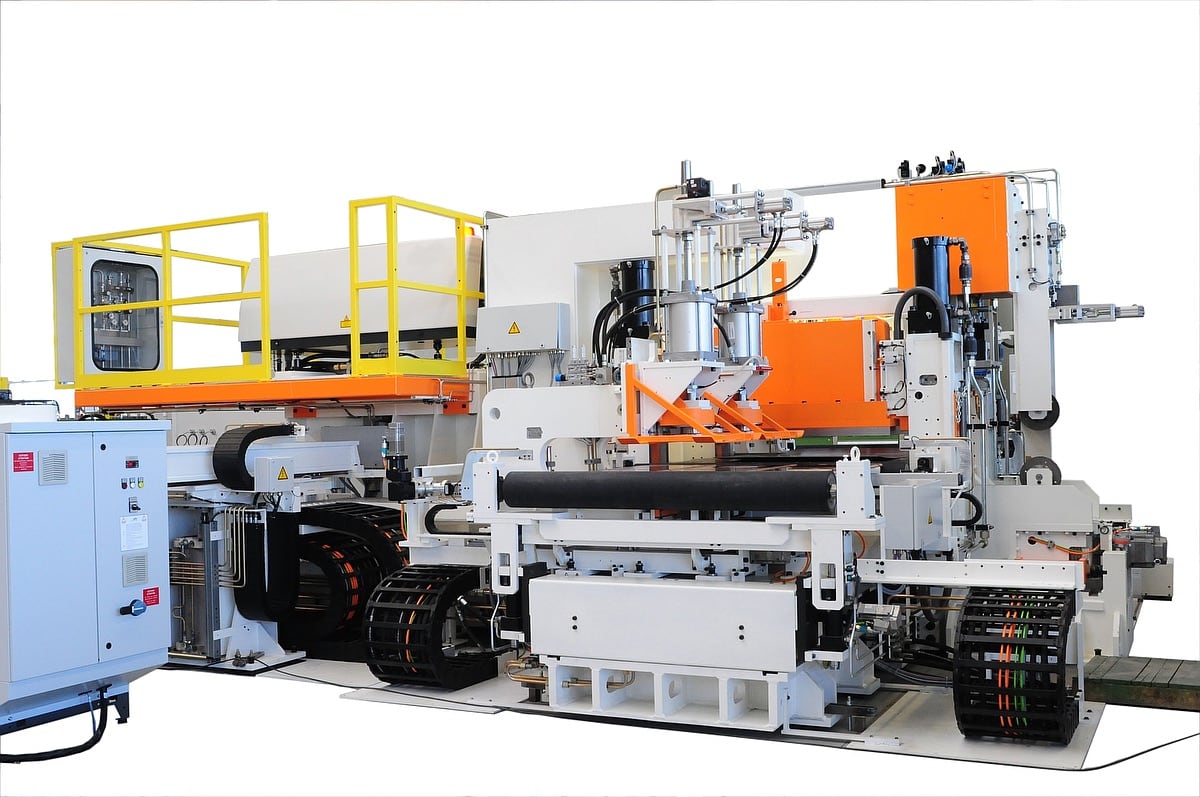

Type LAS coil welding machines

IDEAL laser transverse seam coil welding machines are in widespread use in the steel coil industry, because they meet and comply with the highest requirements in regard to the weld seam quality. Leading steel coil manufacturers rely on the IDEAL model line LAS 200 through 500 coil welding machines in order to optimally cut coils in a single operation and to join them without an overhang of the weld seam. The different types of the LAS line meet all requirements of the steel processing industry and are used at various locations – from the inspection line to the roll train. IDEAL is always your partner for secure, efficient coil joints.

Process steel coils from coil to coil in various dimensions with the type range LAS

Down to the smallest detail: The different types of the LAS model line laser coil welding machines.

Taking a closer look at the details of the type LAS coil welding machines is worth your while. Here you can see the technical details, the typical functional ranges and more detailed information on the technology behind the laser welding machines. You will learn why IDEAL utilises modular mechanical engineering in order to fulfil your requirements and expectations.