Welding solutions for automotive customers

Welding solutions for automotive customers

For many years, we have been an accepted partner of the automotive supplier industry.

Our customers in the automotive sector are national and international companies.

We offer them automated welding machines and robot solutions based on resistance welding technology.

Programmable NC-controlled multi-spot or projection welding machines are available to produce a wide range of joints.

Typical automotive applications for our resistance welding machines are:

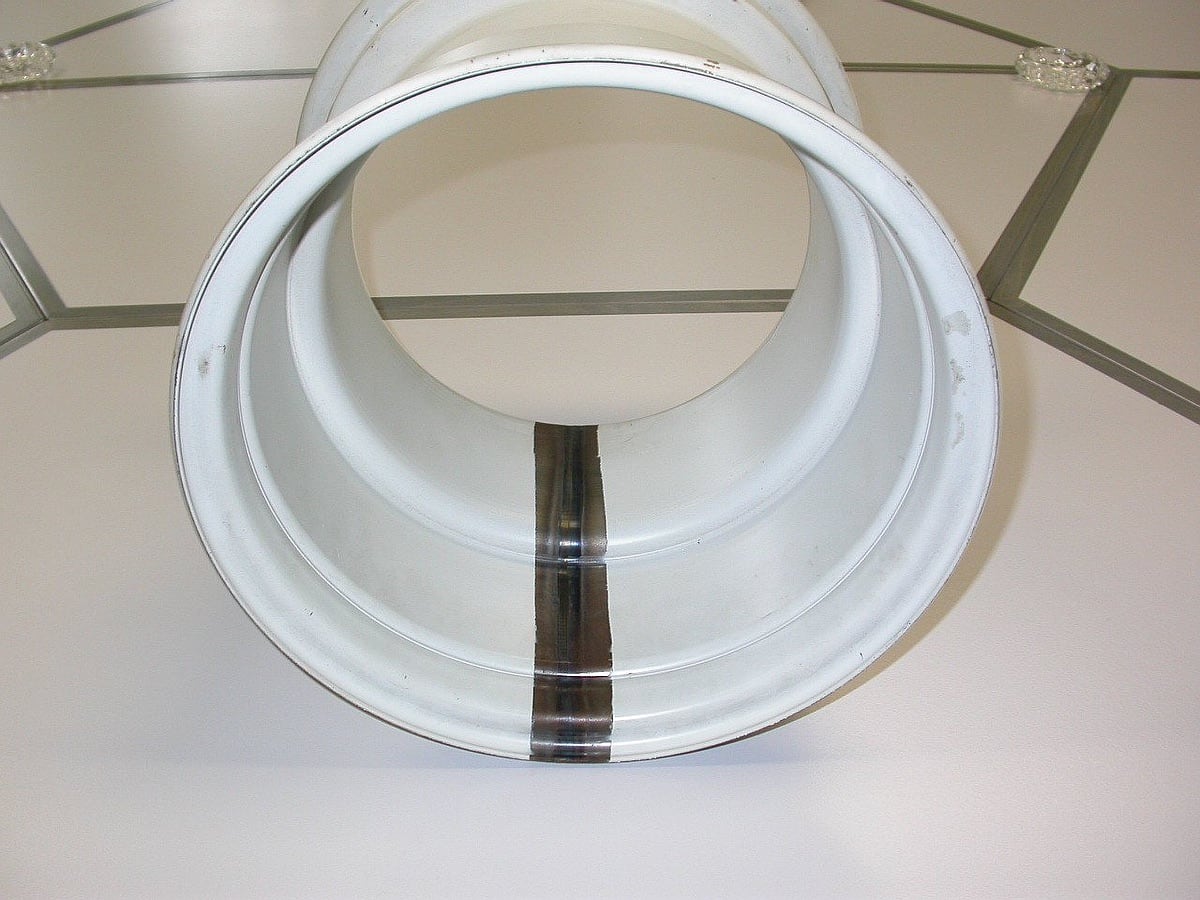

- Rims for motorcycles, cars and utility vehicles

- Starter rings

- Stabiliser bars

- Nut and bolt welds

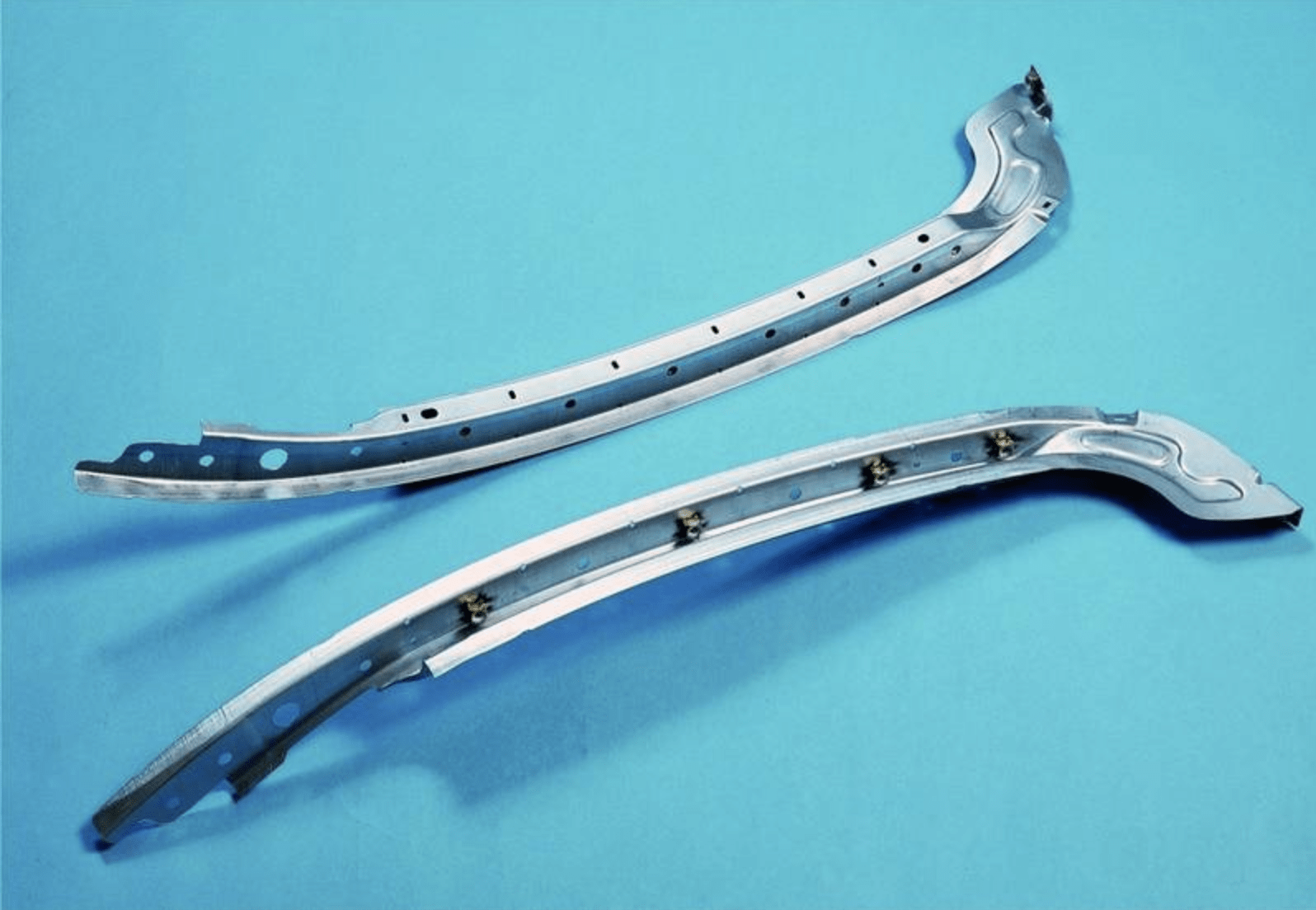

- Reinforcement profiles on doors or chassis

- Seat frames produced from sheet metal, tube or wire

- Lumbar supports

- Aluminium frames for sunroofs

Furthermore, we also design special solutions, such as a production line for particulate filters, for our automotive customers.

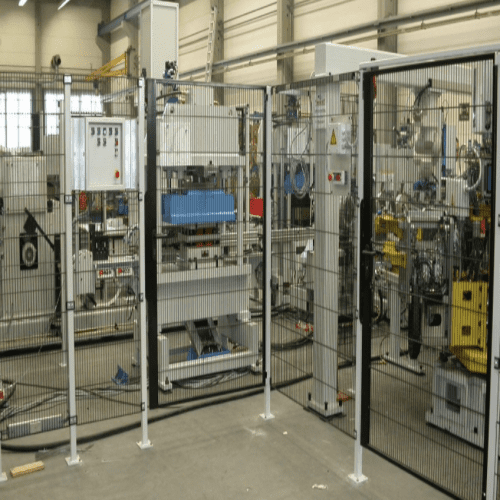

On all machine types, the compact and robust machine design with intuitive operator guidance is oriented towards industrial usage in production.

When designing the machines, the operator was the main focus. For this reason, particular emphasis was placed on easy and ergonomic operation.

Used around the world, IDEAL welding machines have been proving their quality and reliability on a day-to-day basis and have been doing so for decades.

Read the list of the most important features of

- Type AS

- Type VPS

- Type CSR 102 Versaweld™

See also:

- Solutions for the » joining of steel, aluminum and copper wires

» Learn more - Option » dual force welding (DD) process for the processing of non-ferrous metals

» Learn more - Series production of wire products in large quantities

» Learn more

Some application examples:

A wide range of products in the automotive sector can be processed on the resistance welding machines.

Get to know our solutions:

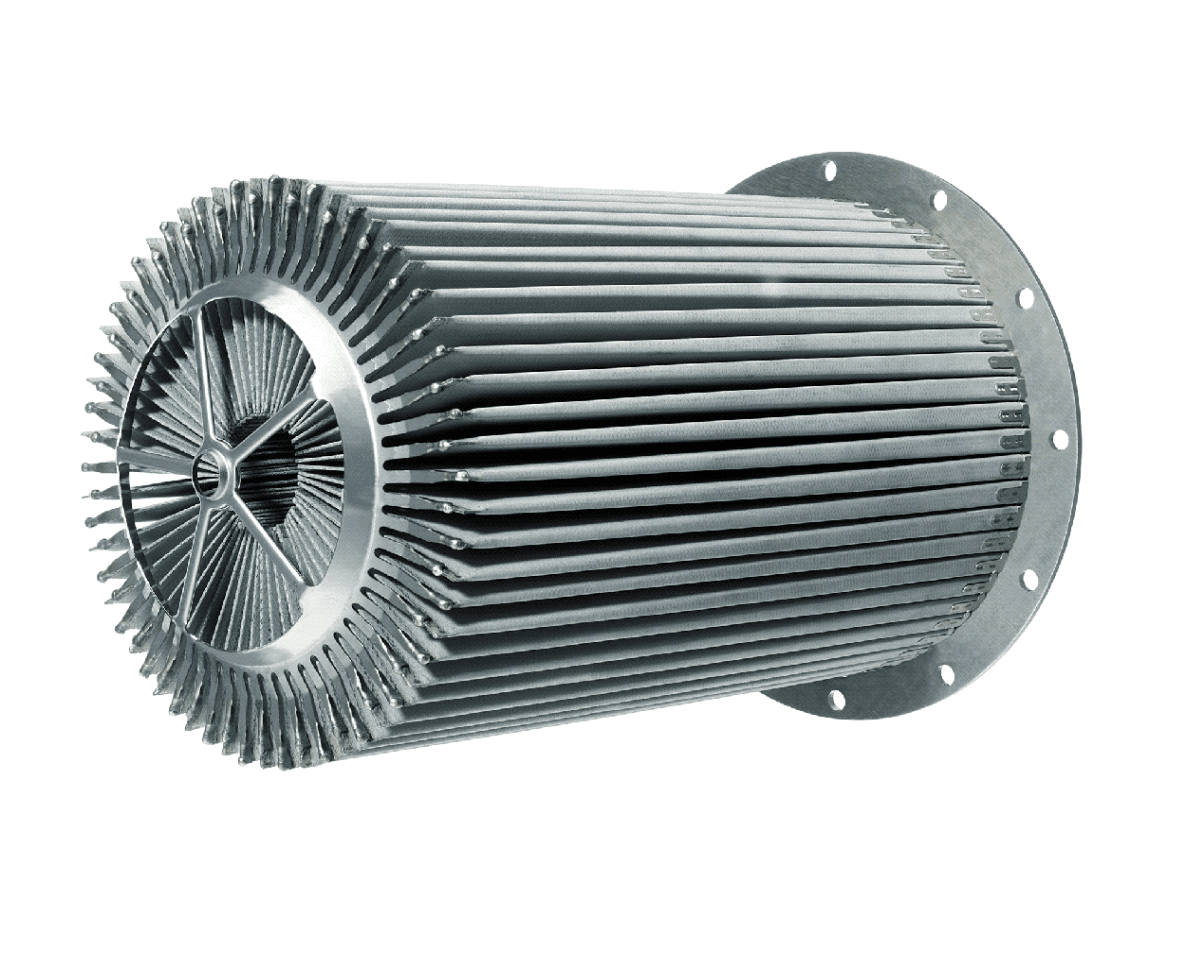

IDEAL is a pioneer in the design and development of flash butt welding machines. Flash butt welding machines of type AS are used in the automotive sector in particular for the economical welding of rims, rings and starter rings.

They are characterised by high welding quality and strength, short welding times and high reproducibility of the welding parameters.

With the use of the most diverse, practically oriented options, the modular constructionof the machine enables the individual implementation of the customer and therefore product-specific requirements..

Dual force butt welding machine

Welding solutions for starter rings in the automotive industry and steel rings in heavy industry

The equipment of the machines type DD0 can be supplemented with various annealing processes (according to the requirements of the material to be processed) and deburring devices as well as machines and devices for welding seam preparation and post-processing.

With the double pressure welding machine DD0 200 from IDEAL-Werk, the heat-affected material made of ferrous or non-ferrous metal is almost completely pressed out of the welding zone after the welding process. This improves the mechanical properties and the construction of the weld. With the DD0 type series, a high welding quality and enormous strength can be achieved. At the same time, the machine is characterized by high reproducibility of the welding parameters and low-spatter welding.

The IDEAL solution for your areas of application in the automotive industry.

IDEAL Dual Force Upset Butt Welding Machine type DD0 200 S-K

For serial welding and deburring of steel rings, radial and axial aligned, clean and dry, shotblasted surface, ring ends in cut quality – manual loading and unloading of rings by operator – Barcode scanner (4.0) as an option.

| Product specification | ||

| Section of rings | ~400 – 1.200 | mm² |

| Width of rings | ~24 – 55 | mm |

| Height of ring | ~18 – 22 | mm |

| Inner diameter of ring | ~345 – 450 | mm |

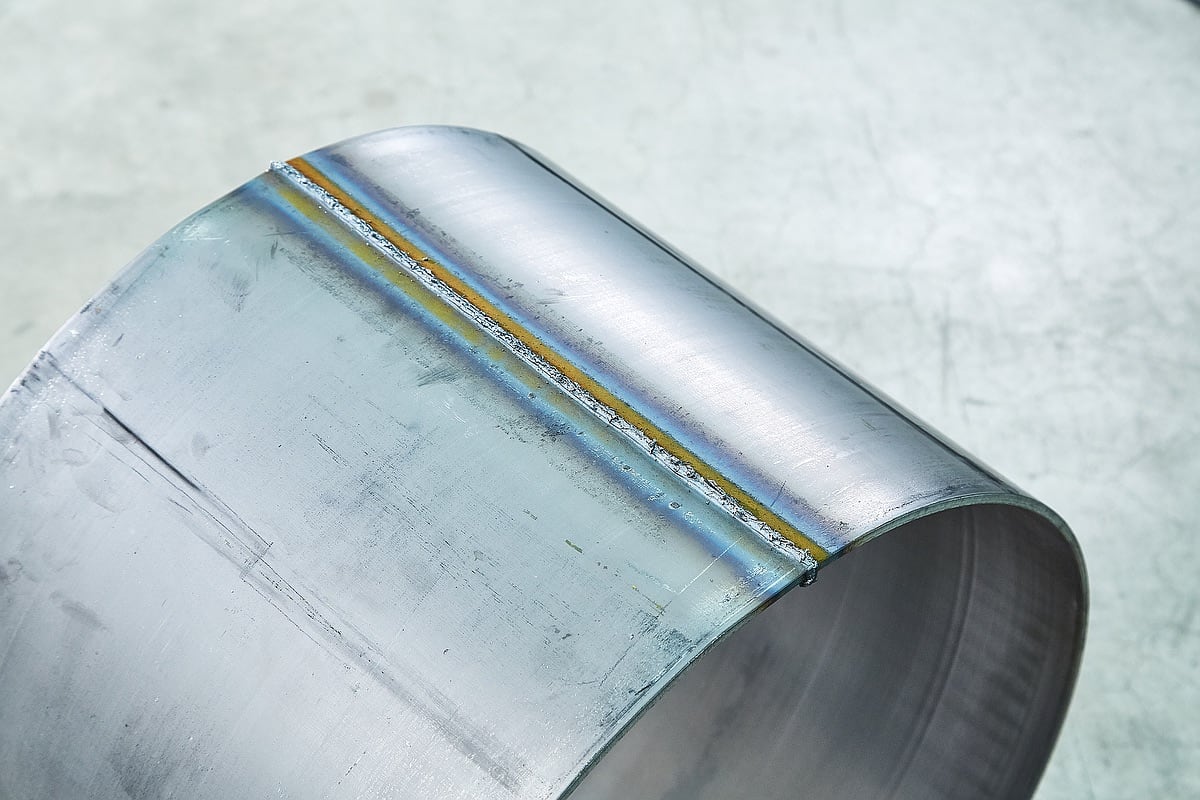

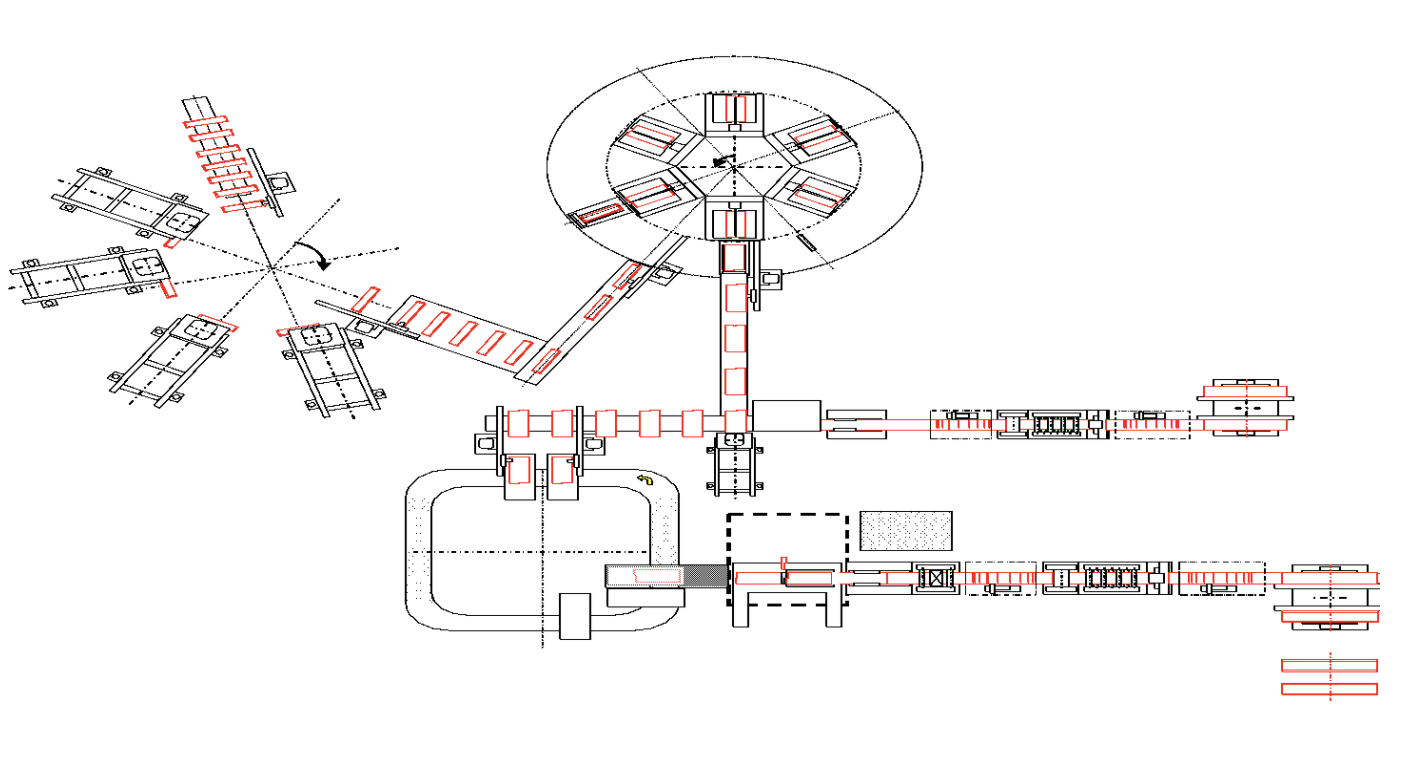

Special production line solution for particulate filters

Working together with our customer’s product development department, we developed the production line for particulate filters as an individually tailored solution.

It was necessary to pay particular attention to the extremely high requirements for product quality, the reproducibility of the product characteristics and the detection of primary material and production defects.

We would be delighted to assist you with the production-oriented product development.

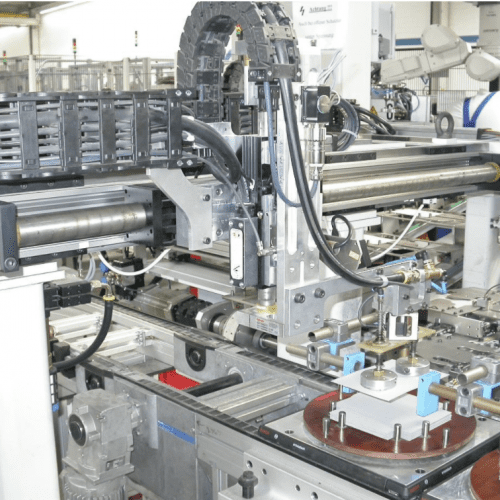

JIG resistance welding machines of type CSR 102 Versaweld™

Die Maschinen vom Typ CSR 102 Versaweld™ können dank ihrer enormen Flexibilität in einer Vielzahl von Anwendungen eingesetzt werden. Der modulare Aufbau mit unterschiedlichsten Optionen erlaubt die individuelle Anpassung an produktspezifische Produkt- und Produktionsanforderungen. Mit der CSR 102 Versaweld™ fertigen Sie hocheffizient dreidimensionale Produkte mit einer Produkthöhe bis 400mm.