Butt welding for wire joining

IDEAL DS and AS series butt welding machines have been specifically designed for the effective joining of steel, aluminium and copper wires. Their strengths lie in the realisation of precise, repeatedly accurate and draw-resistant butt welds. The compact and robust design of the machine with its intuitive operation is aimed at industrial use in wire-drawing mills, cable factories and in wire processing. Depending on the requirement profile, butt welding (DS), flash butt welding (AS) and dual force welding (DD/STS) processes are utilised. Emphasis was on the operator when designing the DS and AS series butt welding machines, with simple and ergonomic operation in mind. Used around the world, IDEAL DS and AS series butt welding machines have been proving their quality and reliability on a day-to-day basis … and have been doing so for decades.

Important features of all machines of the AS and DS series

- Machine housings of a robust design for durability in a challenging production environment

- The layout of electrical components as well as operator/adjustment elements and switches protected from dirt and damage

- Clamping device with high clamping force, attached in a clear and ergonomic manner

- Uniform, high degree of distribution of pressure without the part slipping during the welding process by means of adjustable manual, pneumatic or hydraulic clamping devices (varies according to machine type)

- Perfectly aligned welds by using wear-free, smooth-running and linear-guided and highly accurate guides

- Quick-change electrodes with V or shaped grooves for short fitting times

- Adjustable upset force, current path and jaw distance for optimum welding results

- Upset process by means of a spring package or pneumatic or hydraulic cylinders (varies depending on the machine type)

- Automatic control of the welding process for precisely repeatable welding results

- Precise multi-stage adjustment of the welding voltage for optimum process parameters

Whatever may come – with the excellent IDEAL technology you are always at the cutting edge and optimally equipped to adapt to ever changing technical requirements.

IDEAL type DSH and DSF butt welding machines for the joining of steel, aluminium and copper wires

With IDEAL type DSH and DSF butt welding machines, precise, repeatedly accurate and draw-resistant butt welds are achieved. This robust machine concept with intuitive operation is especially suited for the use in wire-drawing mills, cable factories and in wire processing. Due to the accurate linear welding carriage guide, the machine is also ideally suited for the joining of wire products in single operation. Type DSH machines are equipped with manual clamping devices; the type DSF – for better handling of the wires – is fitted with pedal-actuated clamping devices on an undercarriage. As standard, all type DSH and DSF butt welding machines are already equipped with a device for the annealing of steel with low carbon content. Depending on the respective application, the machines can furthermore be fitted with additional annealing devices. The annealing devices cover the range from simple to electronically controlled as well as automatic annealing temperature control with infrared spectral pyrometer. As a result, even the processing of hard steel wire or specific alloys does not pose any problems. On IDEAL butt welding machines in the equipment variant NE – for the processing of non-ferrous metals – the jaw distance, upset pressure and current path can be set separately from each other even in the basic configuration. Of course, this function is also available for all other machines of the DS series.

OPTION

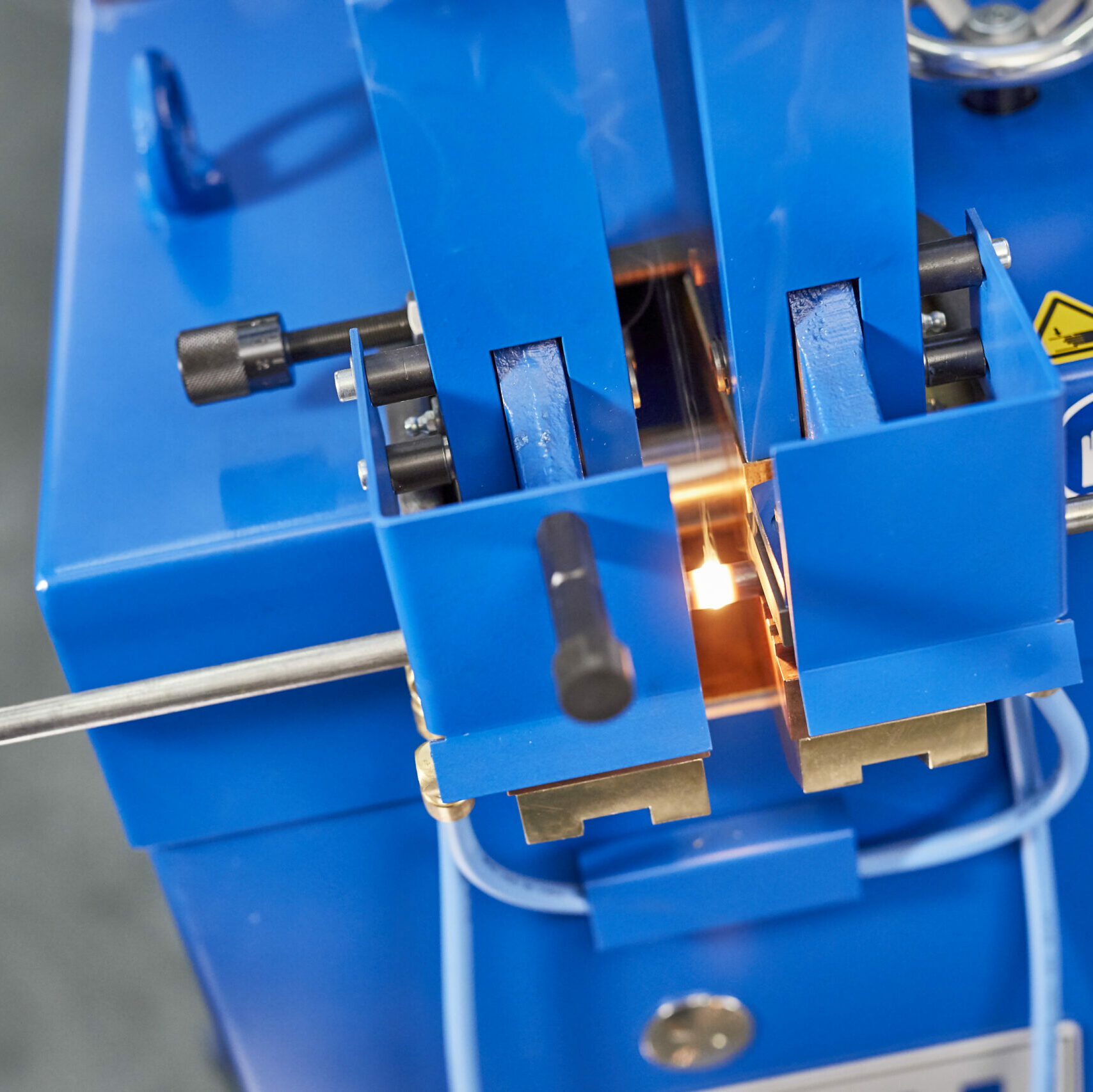

Dual force welding “DD” process for the processing of non-ferrous metals

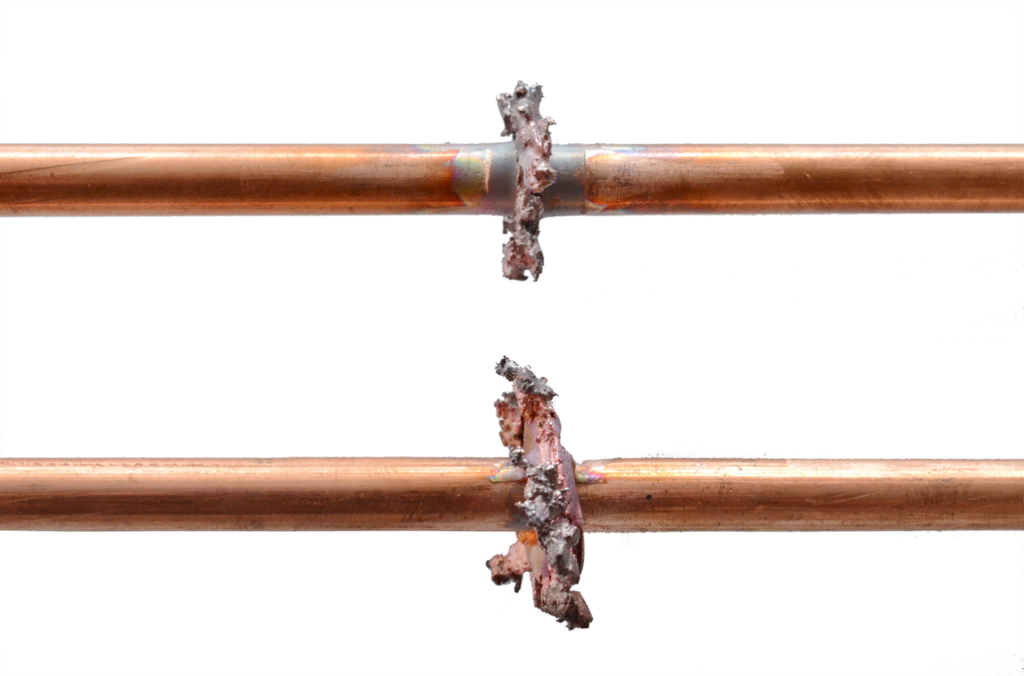

The types DSH 130 and DSH 160 in the equipment variant NE can be equipped with the dual force welding “DD” process. During the dual force welding process, an additional upset blow is performed during the welding process. This additional force application presses the heat-affected material almost completely out of the weld zone. Thus a finer grain structure is achieved in the heat-affected zone and as a result the mechanical properties of the weld seam are improved. In this manner, even high-strength joints can be achieved! The key advantages of the dual force welding “DD” process are:

- Finer grain structure

- High tensile strength

- High bending strength

Micrographs

Type DSP butt welding machines for the series production of wire products in large quantities

IDEAL type DSP butt welding machines have been designed for the effective joining of wire products for series manufacturing in the industrial production environment. The robust machine concept is equipped with pneumatic clamping devices as well as accurate, linear-guided weld carriages. Due to the easy and intuitive operation as well as the automated sequence of the weld, large quantities are achieved during the production of rings, frames, shaped parts and other articles made of round and profiled wire. Type DSP machines are suited both as a manual workplace as well as for the integration in production lines. For the demanding continuous operation, the electrodes have been prepared for water cooling – depending on the requirement, the same also applies to the transformer. In addition to the conventional butt welding, with the MIS option, multi-pulsation welding, low-burr welds can be achieved, which require little or no post-processing.

Product video: IDEAL Typ DSP 120

Wire butt welding machine for series production

IDEAL type DST butt welding machines for the fabrication of T-joints and linear welds

Our type DST butt welding machines can join wires both in T-joints as well as in linear joints in large quantities. The robust machine concept is equipped with pneumatic clamping devices as well as accurate, linear-guided weld carriages. The strengths of the IDEAL type DST butt welding machine lie in the creation of precise, draw-resistant and repeatedly accurate butt welds as well an intuitive, easy to learn and ergonomic operability. The automated sequence enables short cycle times. For the demanding continuous operation, the electrodes have been prepared for water cooling – depending on the requirement, the same also applies to the transformer. The integration in production lines is achieved easily and in a straightforward manner with the optional interface. The continuously variable adjustment as well as the path- or time-dependent deactivation of the welding current enables the individual consideration of the requirements of the material being processed, thus ensuring optimal welding results. The parameter input is performed via a graphic user interface. With the MIS option – multi-pulsation current control – low-burr welds of steel wires with low carbon content can be achieved, which require little or no post-processing.

Product video: IDEAL Type DST 120

Draht-Stumpfschweißen in T- und Linienstößen

Type AS flash butt welding machines for the highest productivity in the heaviest of industrial use with the highest strength of the joint

In order to achieve the highest possible tensile strength and the related fulfilment of the standard requirements, IDEAL type AS flash machines are the means of choice. The automated sequence of the welding begins with the preheating of the wire ends followed by the flashing. It is ended with the welding process. Even in the standard version, all type AS machines are equipped with hydraulic clamping devices. The equipment of the type AS machines can be supplemented with different annealing processes (in accordance with the requirements of the material to be processed) and deburring devices, as well as machines and devices for pre- and post-treatment of welds. Benefits of the flash butt welding of steel and aluminium wires with our type AS machines:

- Finest welding quality with metallurgical clean joints; strengths of approx. 90% (related to the base material)

- Short welding times (depending on the wire diameter only a few seconds are required)

- Low requirements for the preparation of the wire ends (any unevenness and contamination in the joint have little effect on the process)

- High reproducibility of the welding parameters; optionally an effective monitoring and the regulation of the welding process is possible

- High dimensional accuracy of the welded wires due to the tight length tolerances

IDEAL is one of the pioneers of the flash butt welding technology — since 1923. For more information on this machine type, please click here.

Product video IDEAL AS0 15

Abbrennstumpfschweißmaschine zur manuellen Herstellung von zweiteiligen Zugstäben

Double pressure welding machine for ferrous and non-ferrous metals

IDEAL STS 020 to DD0 104

The double pressure welding process is used especially in wire drawing shops.

With the double pressure welding machine DD0 104 but also the STS 020 from IDEAL-Werk, the heat-affected material made of iron or non-ferrous metal is almost completely pressed out of the welding zone with force after the welding process. This improves the mechanical properties as well as the design of the weld. With STS or DD0 type series, high welding quality and enormous strength can be achieved. At the same time the machine is characterized by a high reproducibility of the welding parameters.

The ideal solution for your applications in coil vertical haul-offs of stretching lines and drawing lines.

Product video of the IDEAL STS 020

Butt welding machine STS 020 – vertical

Product video IDEAL DD0 104

Double pressure welding machine for ferrous and non-ferrous metals