Type BAS 300 flash butt welding machines

Type BAS 300 flash butt welding machines

The IDEAL BAS series is the result of more than 90 years of design and construction experience in the field of band saw joints. It is impressive in particular due to its high speed, short set-up times and fast product changes. Systematic research and development, highly qualified personnel and continuous collaboration with our customers have made us one of the world’s leading suppliers of flash butt welding machines for band saws. During the designing of the BAS 300, the worker was the main focus. For this reason, particular emphasis was placed on easy and ergonomic operation. On all machine types, the compact and robust machine design with intuitive operation is oriented towards industrial usage in production. Used around the world, IDEAL flash butt welding machines have been proving their quality and reliability on a day-to-day basis and have been doing so for decades.

Advantages of the flash butt welding machine BAS 300

Down to the smallest detail: The flash butt welding machine BAS 300

Down to the smallest detail: The flash butt welding machine BAS 300

A look at the details of the BAS 300 is worthwhile. Here you can see the technical details, the typical functional ranges and more detailed information on the technology behind the flash butt welding machines. You will learn why IDEAL utilises modular machine construction in order to fulfil your requirements and expectations.

Optional modules for the type BAS 300 butt welding machine

For the BAS series, IDEAL offer a multitude of supplemental modules in order to make your machine modularly more efficient and incorporate it optimally in your production.

Accessories for the pre- and post-processing of strips for all machine types

You can add to and expand your strip grinding machine with different components to suit your needs. These include various designs of strip shears and grinding machines that can be added directly to the machines for the further processing of the welded strips and band saws.

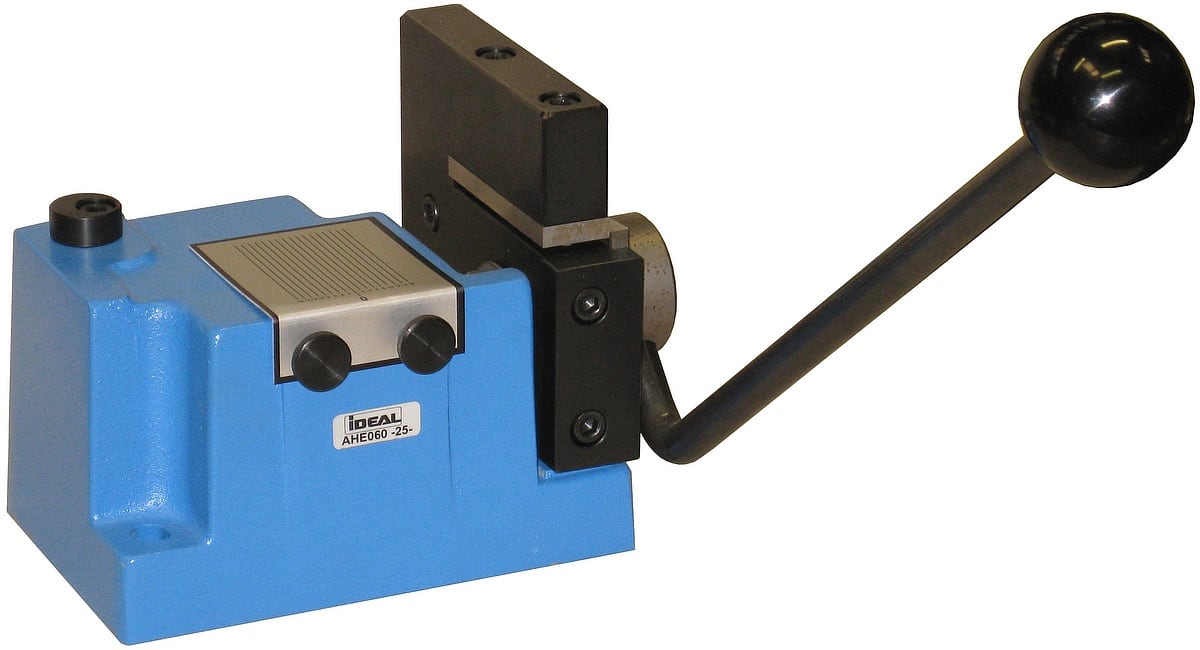

Shears

IDEAL APE strip shears for the burr-free and right-angled cutting of strips as the first step for a high-quality strip join

Grinding machines

IDEAL-SMH or, as may apply, SMP grinding machines for machining the weld of strips with a width of up to 320 mm