Individual special solutions for your welding requirement.

Individual special solutions for special welding requirements

Since our foundation in 1923, IDEAL has been characterised by ever-growing success. This is the result of the continuous technical further development and quality of our machines and systems. The special machines, which are developed in accordance with the individual needs of our customers, are an important mainstay of IDEAL. After determining the customer’s problem or issue, our design department seeks and identifies the optimum technical solution, and then designs, manufactures and tests the machine until it is ready for operation. Flexibility and tailored, customer-oriented solutions are the roots of our high innovative strength here. On all machine types, the compact and robust machine design with intuitive operator guidance is oriented towards industrial usage in production. When designing the special machines, the operator is the main focus. For this reason, particular emphasis is placed on easy and ergonomic operation. Used around the world, IDEAL welding machines have been proving their quality and reliability on a day-to-day basis and have been doing so for decades.

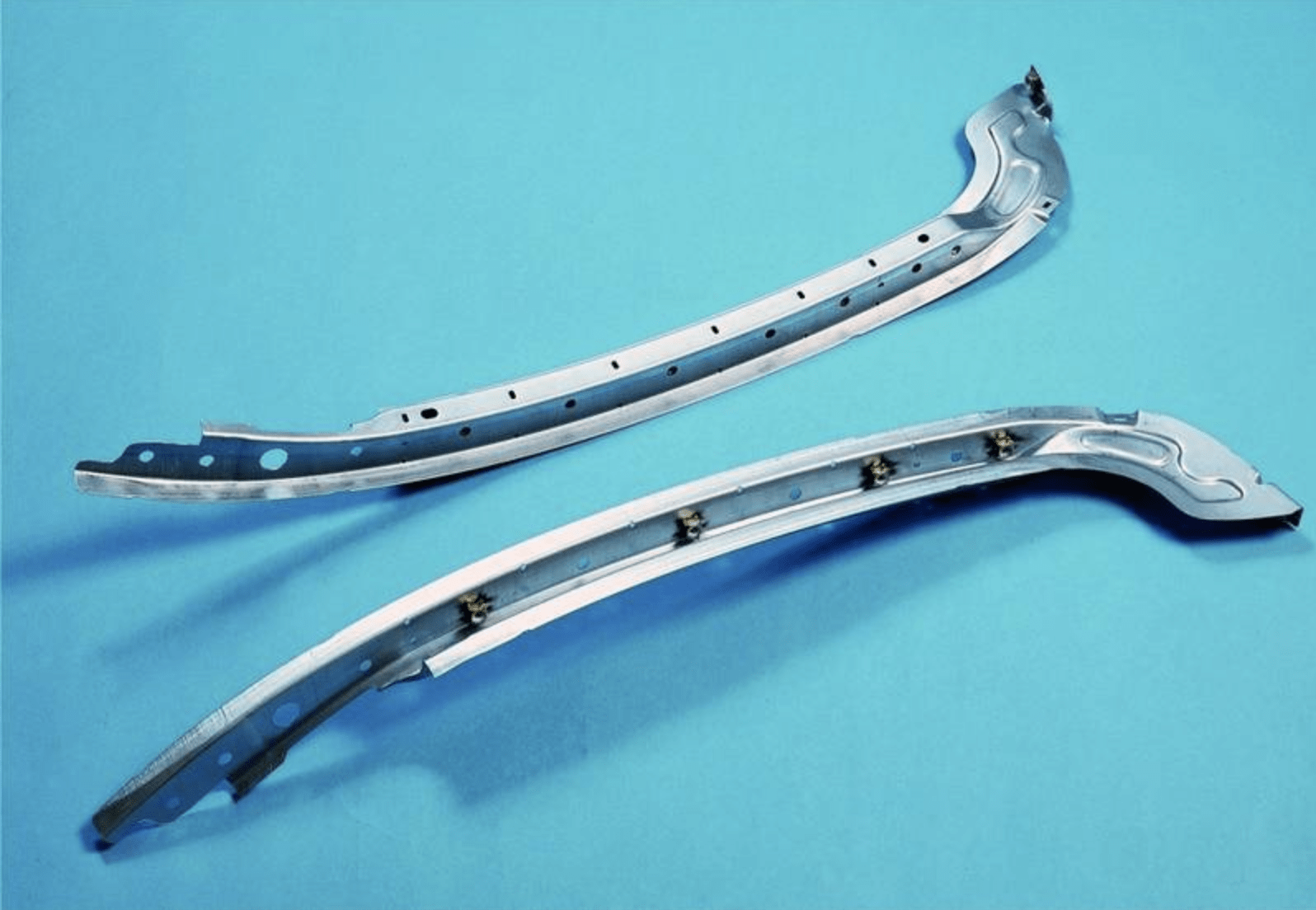

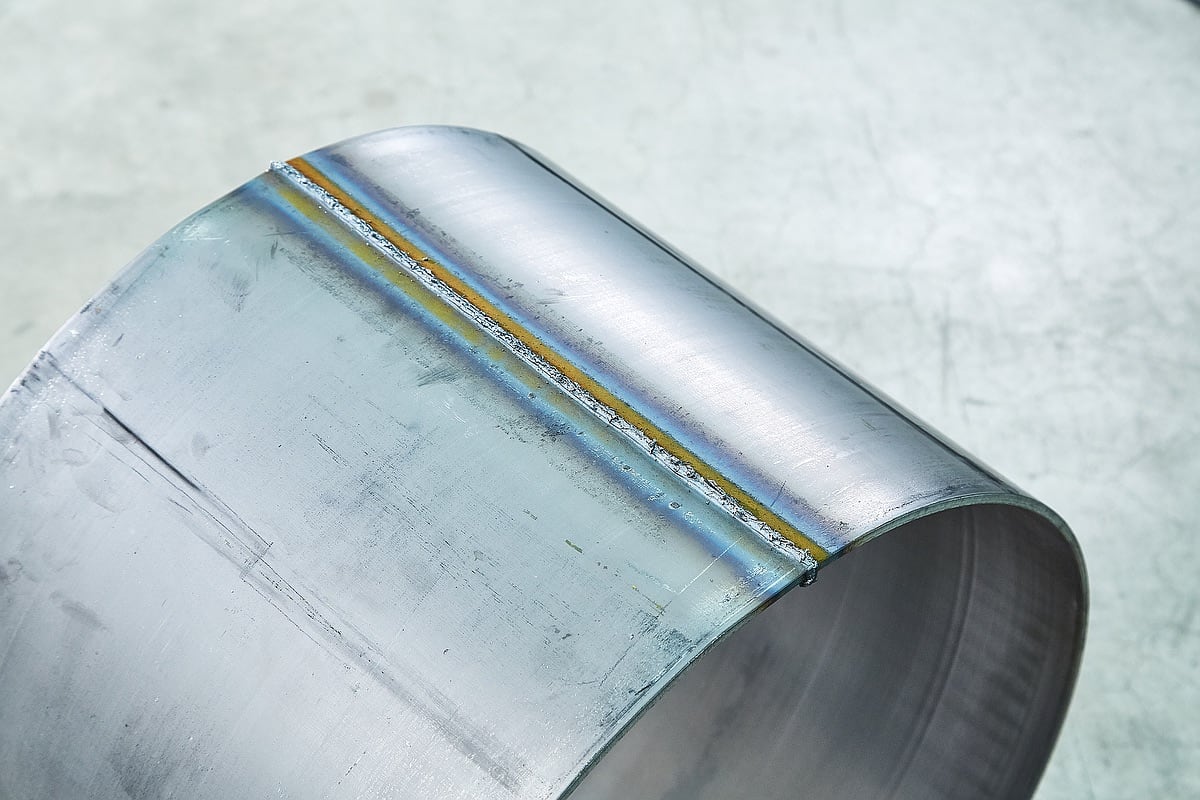

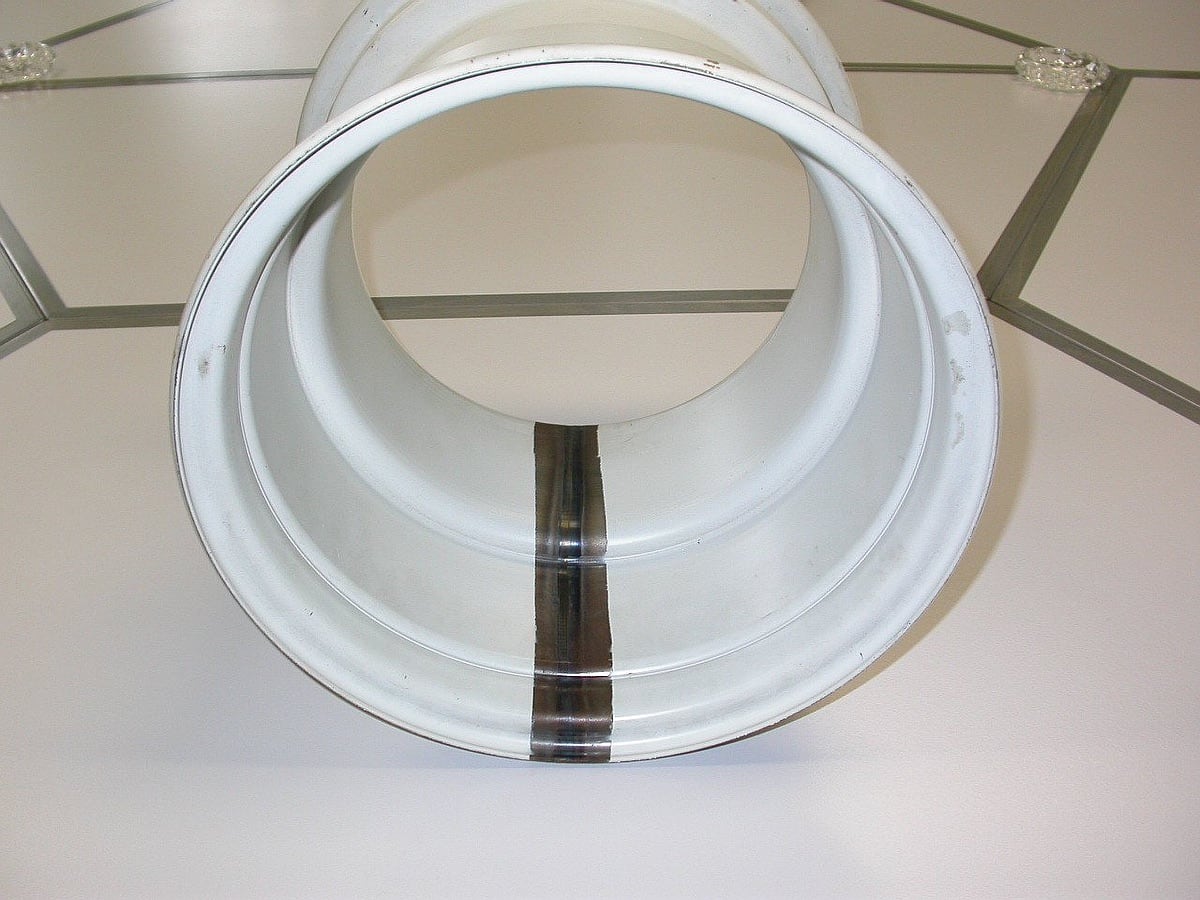

Some product examples:

A wide range of products are manufactured using customer-specific special machine solutions from IDEAL.

Examples of the latest special solutions:

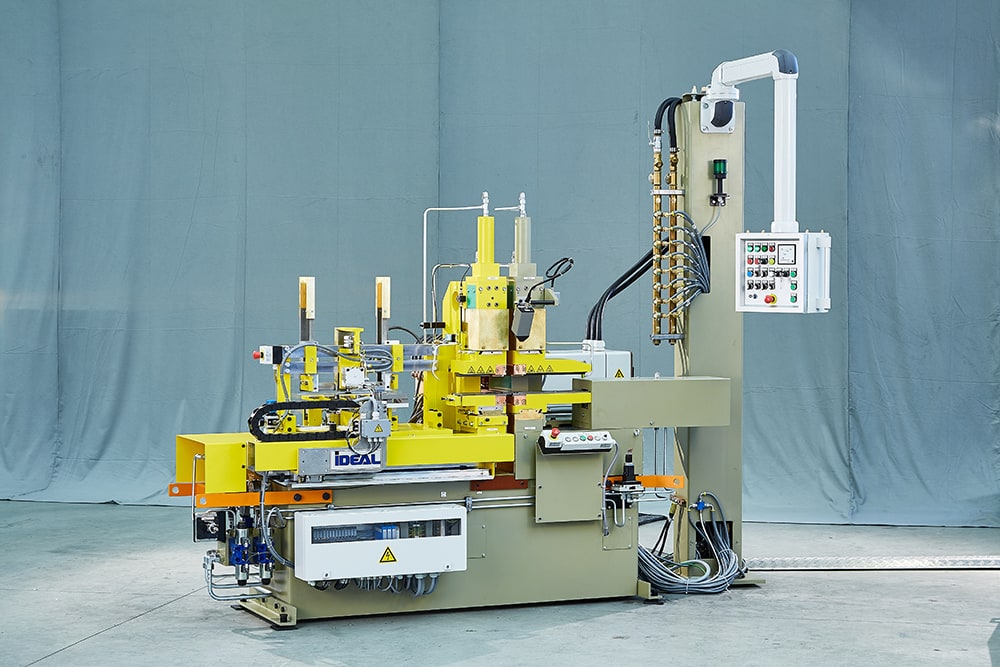

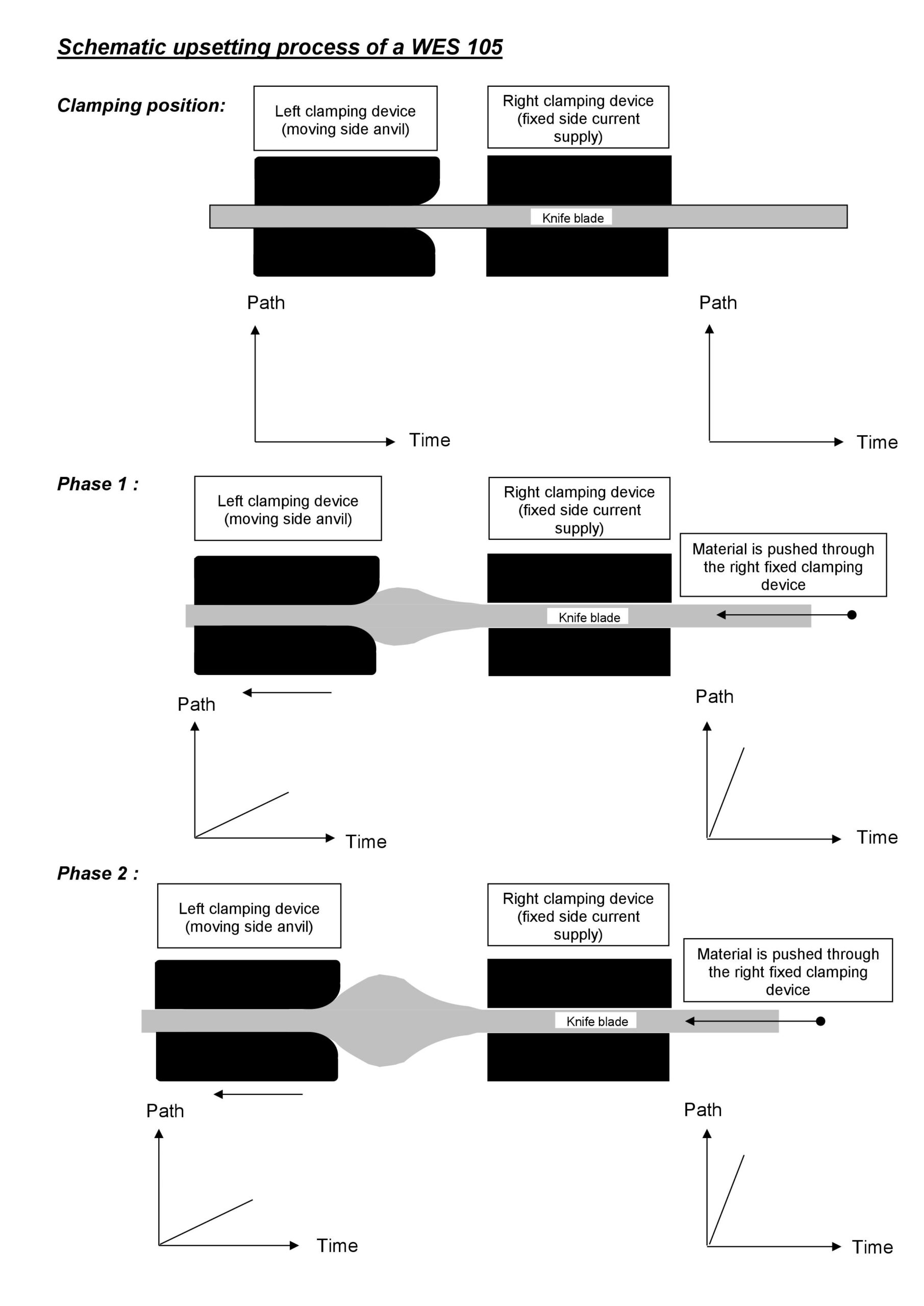

Resistance upsetting machine type WES for the production of bolster-upsetting on professional knife blades

The resistance upsetting machine shown on the left is used to produce bolster-upsetting on professional knives. The machine was designed and developed by IDEAL as a special machine in accordance with customer requirements. The material pre-heated by the machine in advance is upset in the next process step. The clamping pressure and jaw distance can be adjusted to the material to be upset.

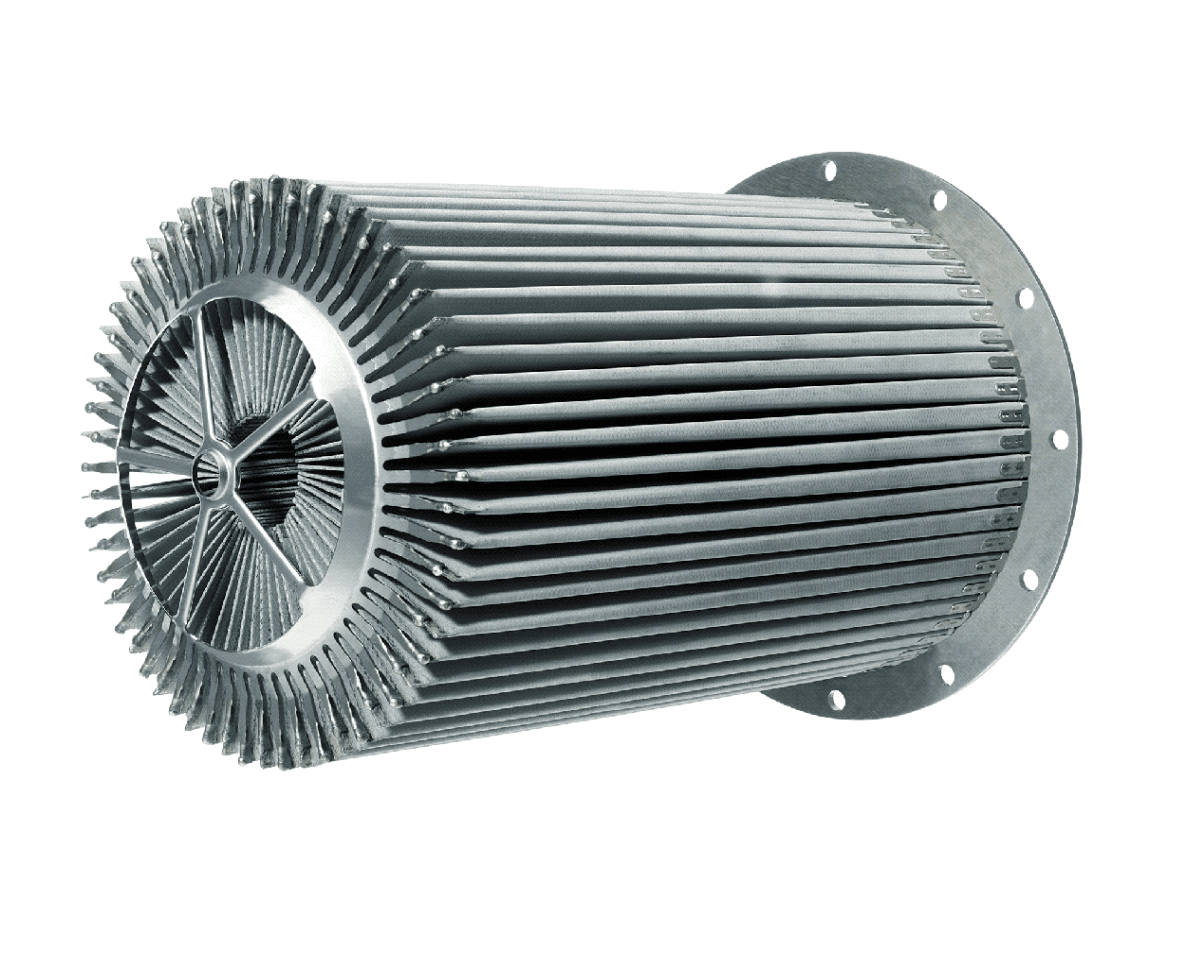

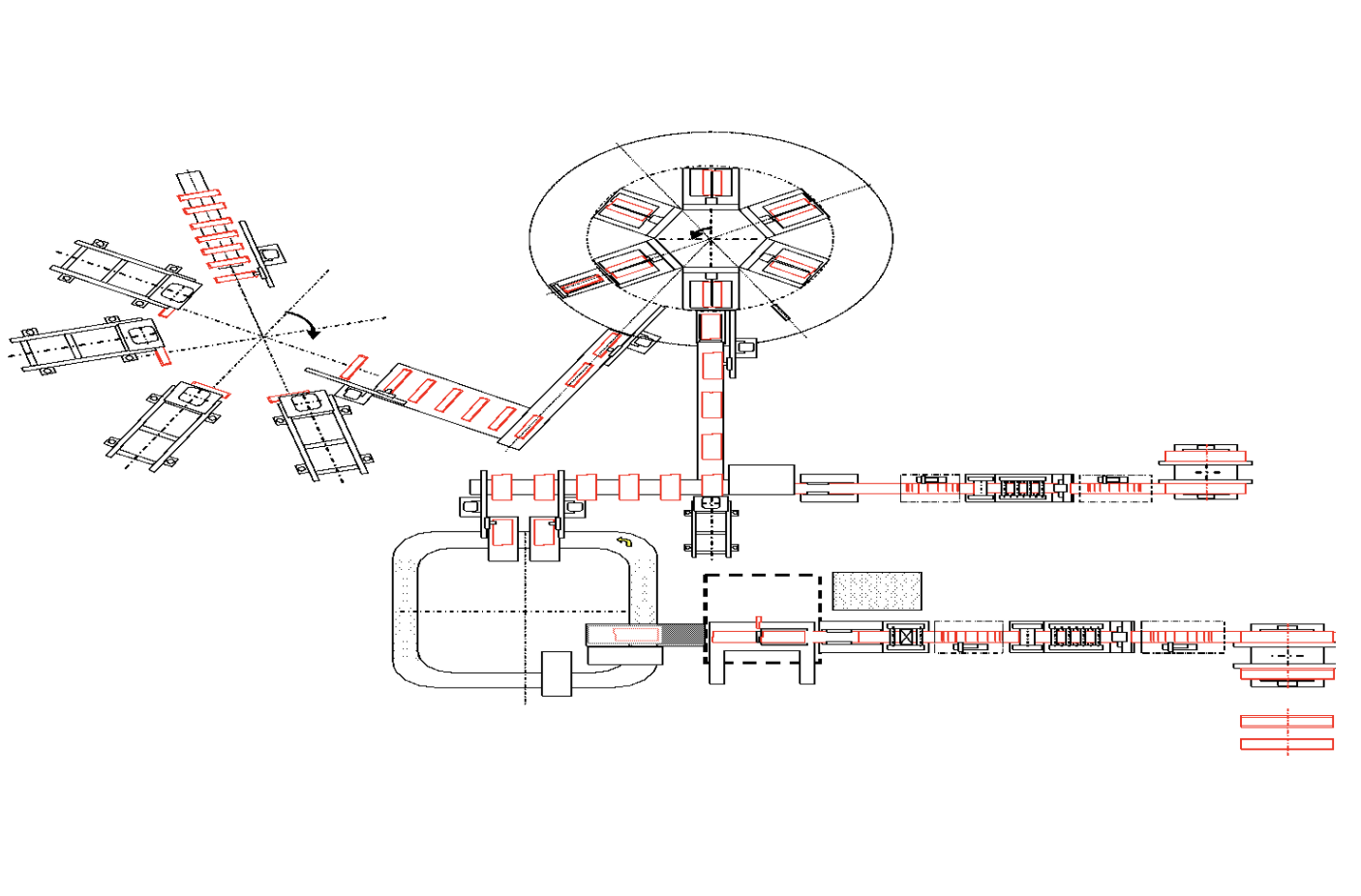

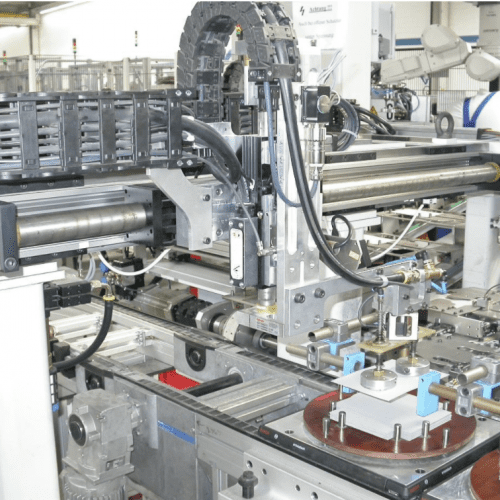

Special production line solution for particulate filters

Working together with our customer’s product development department, we developed the production line for particulate filters as an individually tailored solution. It was necessary to pay particular attention to the extremely high requirements for product quality, the reproducibility of the product characteristics and the detection of primary material and production defects. We would be delighted to assist you with the production-oriented product development.

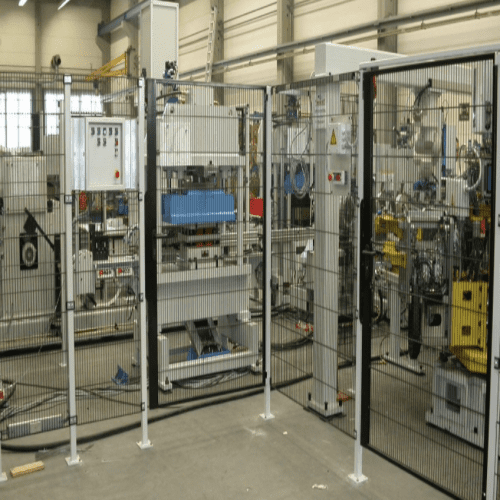

The CSR 102 Versaweld™ jig welding machine

The machines of type CSR 102 Versaweld™ are characterised by their diversity, as well as a high degree of flexibility. With the use of the most diverse, practically oriented options, the modular construction of the machine enables the individual implementation of the customer and therefore product-specific requirements. With the CSR 102 Versaweld™ you can manufacture highly efficient three-dimensional products with a product height of up to 400mm.