Optimal welding solutions for mesh production of wire products/goods

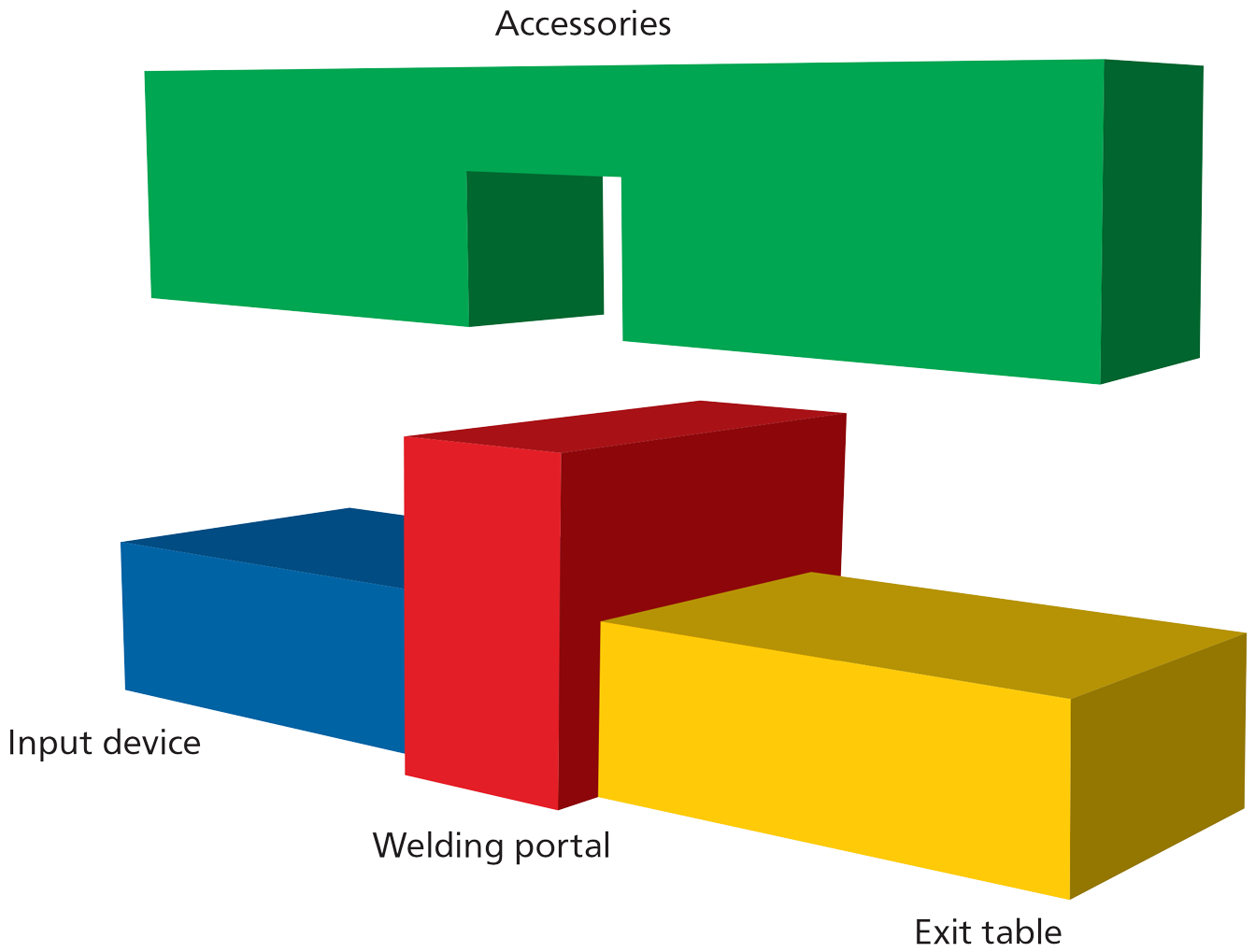

Our mesh welding machines in particular distinguish themselves with a modular construction. In this manner, solutions tailored for the respective application can be realised for a large variety of applications. This modular construction enables an individual implementation of the customer- and product-specific requirements. This facilitates speed and flexibility in your production. The jig welding machine CSR is best suited for the flexible production and combination of diverse 3-dimensional wire and sheet metal products in small quantities. The GA type mesh welding machines have been specifically designed for the fabrication of flat mesh for wire products of all types in large quantities. On both machine types, the compact and robust machine design with intuitive operator guidance is oriented towards industrial usage in production.

During the designing of the machine, the operator was the main focus. For this reason, particular emphasis was placed on the simple and ergonomic operation. Used around the world, IDEAL mesh welding machines have been proving their quality and reliability on a day-to-day basis and have been doing so for decades.

DOWNLOADS

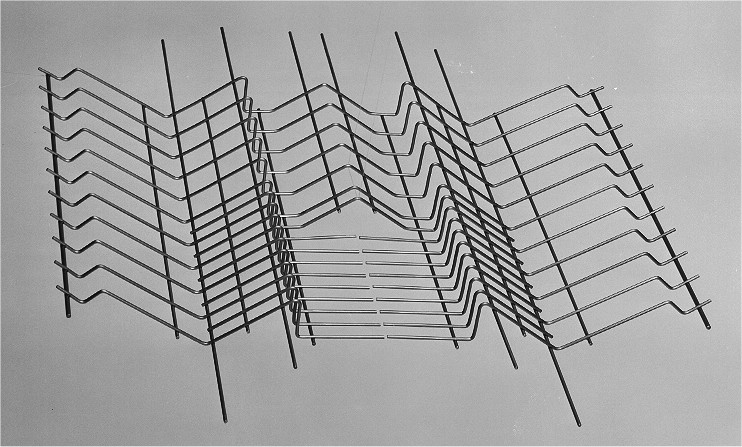

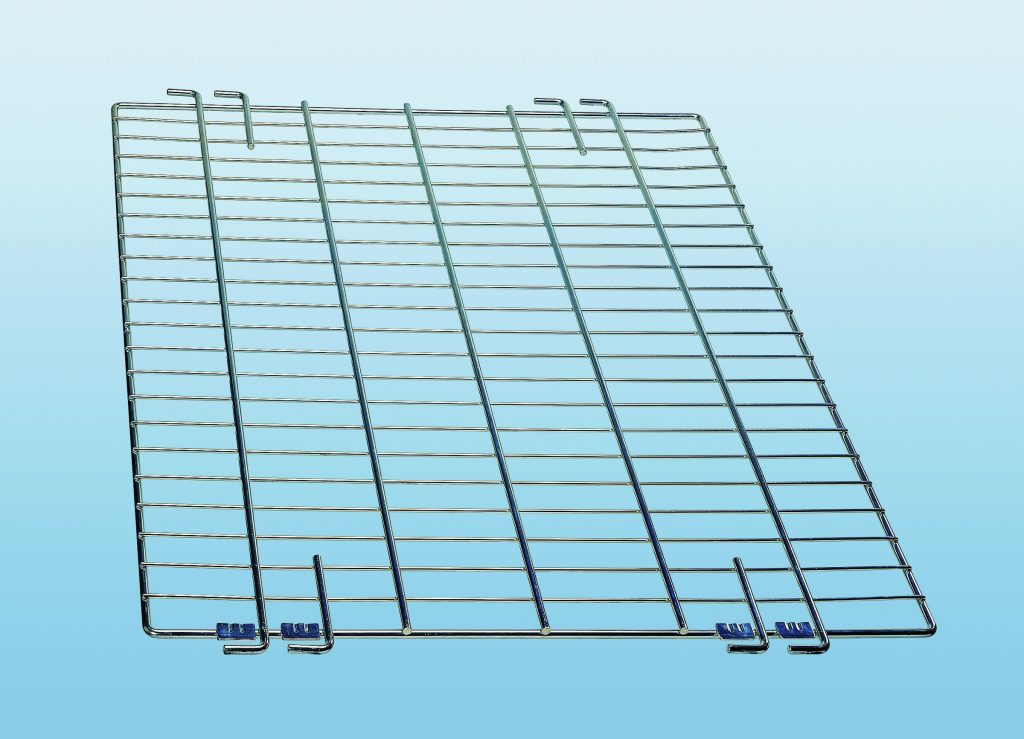

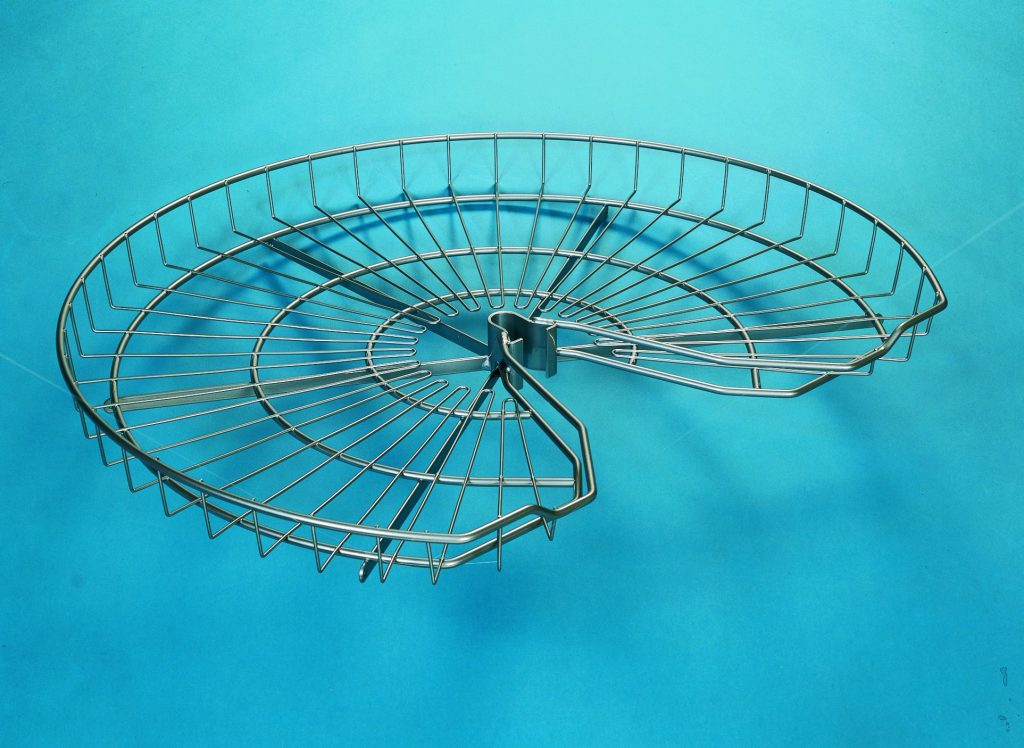

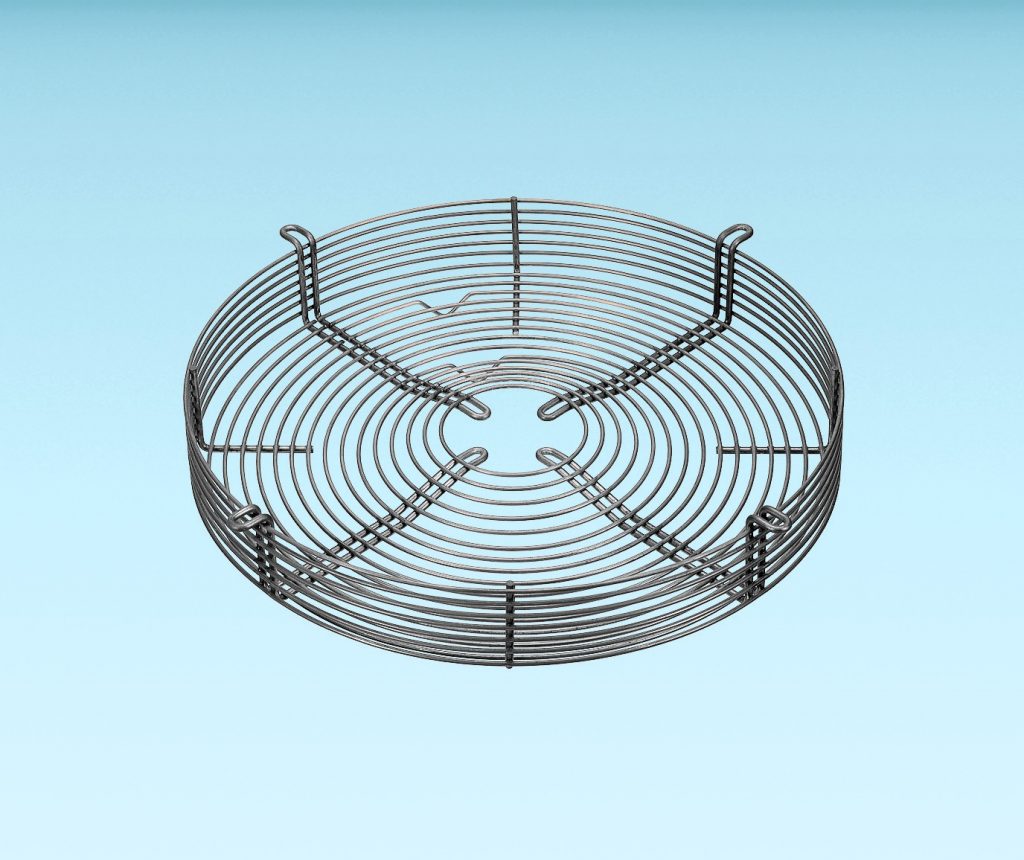

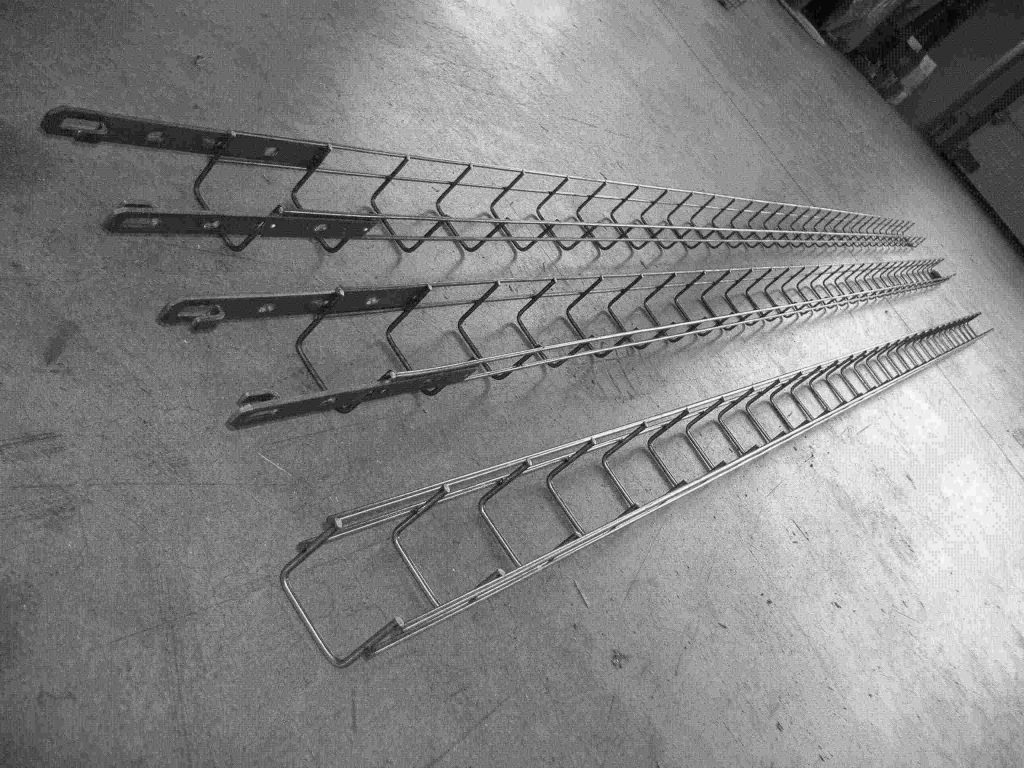

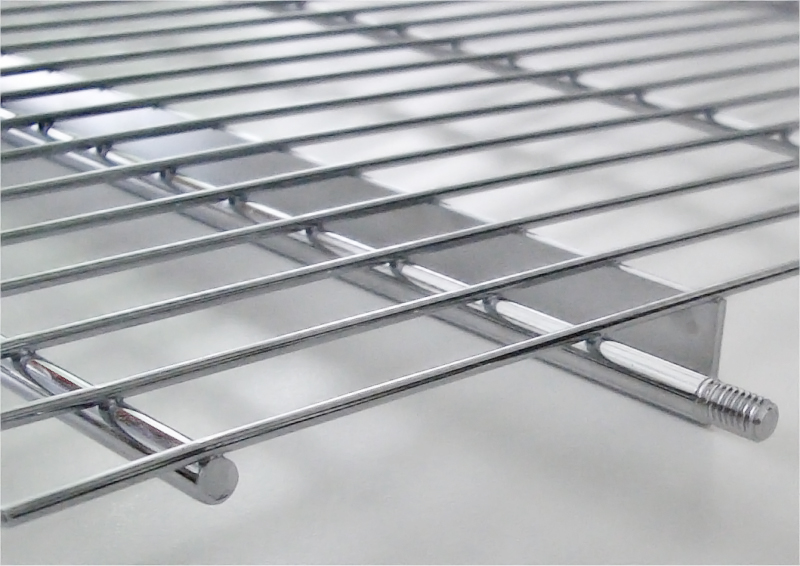

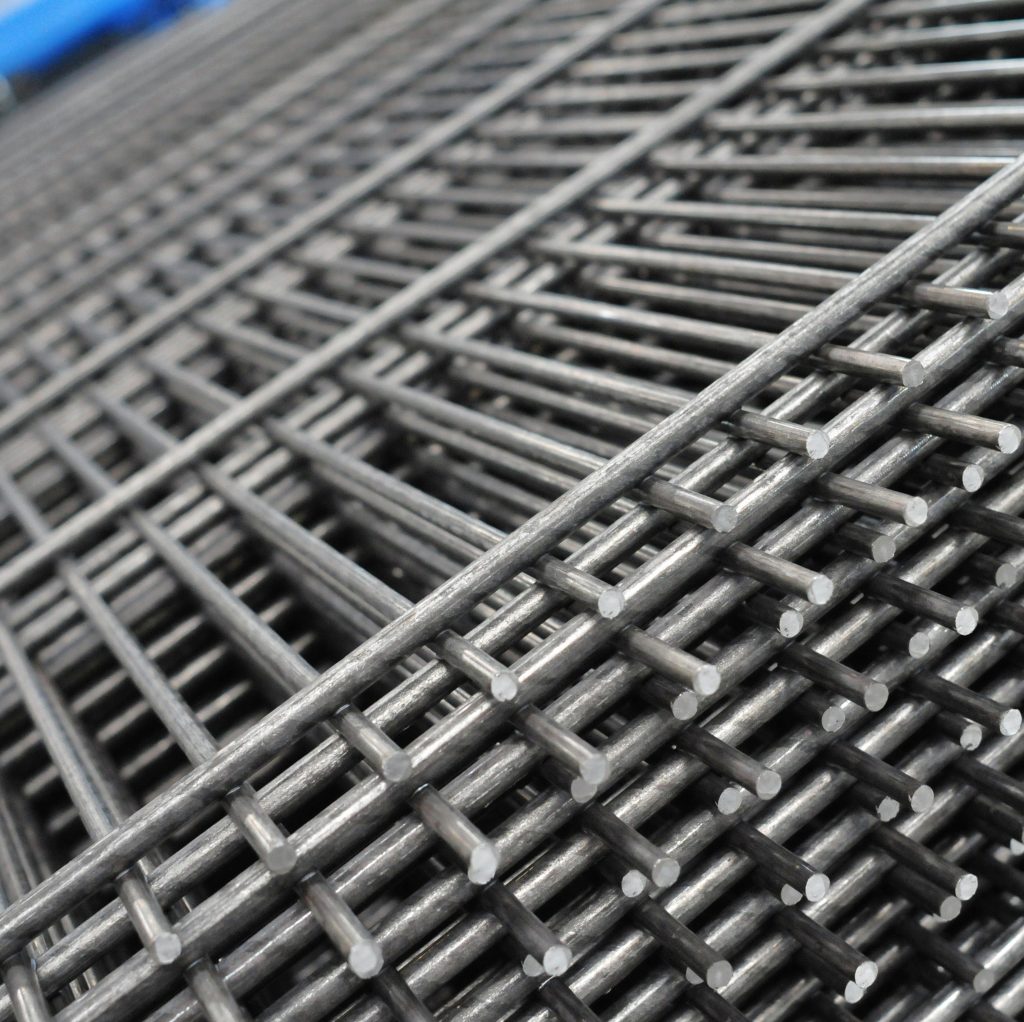

Application examples

Diverse material combinations such as wire, sheet metal, flat strip and much more can be realised with the flexible welding machines GA and CSR Versaweld™.

Get to know our solutions

GA type mesh welding machines

Our GA type mesh welding machines are utilised worldwide in the wire goods industry. Leading manufacturers of wire goods choose these reliable machines in order to be able to produce the base mesh for their products in a flexible and highly economical manner. The mesh welding machine type GA can be augmented with several processing steps such as punching, embossing, bending, etc. to form an automated production line. In this manner, the wire is transformed in a single pass into a product ready for sale.

Jig welding machine CSR

Due to their enormous flexibility, the machines of the type CSR can be utilised in a multitude of applications. The modular construction with the most diverse options permits the individual adaptation to product-specific product and production requirements. With the CSR, you will manufacture three-dimensional products with a product height of up to 400 mm in a highly efficient manner.

Welding technology

Depending on the respective welding task and product requirement, IDEAL utilises alternating current, direct current or medium frequency technology (1,000 Hz). As a result of the concentration of the current to the respective cross point, straight, distortion-free and dimensionally accurate grates are achieved. Furthermore, with the programmable cascading of individual welding areas, the use in production facilities with limited power supply is also possible.

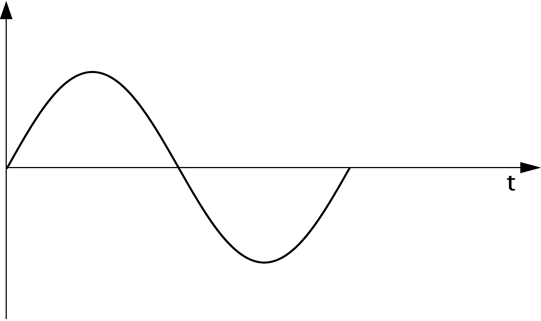

Alternating current

The mains frequency generally is 50 Hz per second (in some countries 60 Hz is also used). This means that a period corresponds to 20 milliseconds. Due to the high proportion of reactive current, the degree of efficiency with alternating current welding units lies at approx. 65%.

Alternating current AC 50 Hz

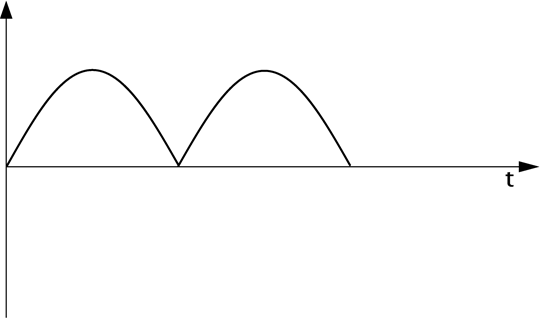

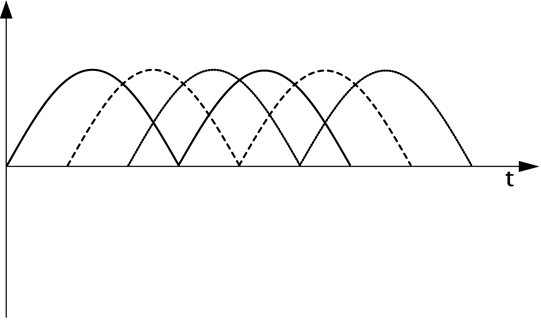

Direct current

A distinction is made between single-phase and three-phase direct current with direct current welding units. With single-phase direct current, only one of the three phases is loaded, as a result of which an asymmetric network load is generated. With three-phase direct current, all three phases are loaded evenly, resulting in a symmetrical network load. Due to the rectification of the current as well as the specific construction of the welding portal, the current can only flow in a single direction. With direct current welding machines, the degree of efficiency lies at approx. 75% to 85%. The cross currents are minimised significantly as a result of the direct welding (reduced introduction of heat). This results in reduced welding currents, shorter welding times as well as an increased service life of the electrodes.

1-phase direct current DC 50 H

3-phase direct current DC 50 Hz

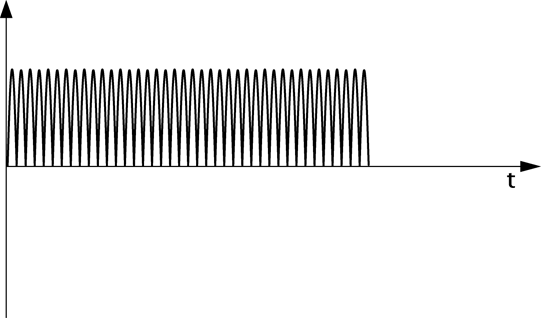

Medium frequency (1000 Hz technology)

On our medium frequency units, the welding transformer is driven with 1000 Hz (20 x faster than AC with 50 Hz). Here, a period corresponds to 1 millisecond. Due to the high frequency, the welding time can be set considerably finer. The degree of efficiency of medium frequency welding machines lies at approx. 95-98%. The cross currents are minimised significantly as a result of the direct welding (reduced introduction of heat). The result is a significantly flatter product. As a result of the 3-phase connection of the control electronics, a symmetrical network load is achieved and leads to a reduction of the connected load.

DC medium frequency rectified 1000 Hz